Prefabricated homes have gained prominence as a viable, sustainable, and economical alternative to traditional construction. Their success is not only due to speed of assembly or cost savings, but also to technological advancements in materials, manufacturing processes, and energy-efficient systems.

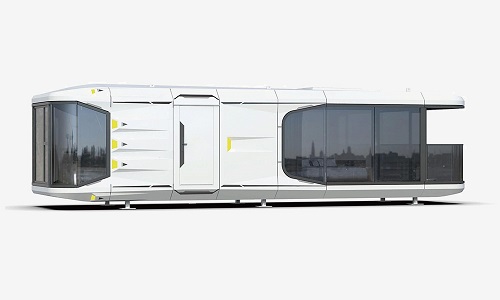

A prefabricated home is partially or fully manufactured in an industrial plant and then transported to the site for assembly. This contrasts with conventional construction, in which each element is built directly on site.

Although they offer numerous advantages, there are technical aspects that require attention to ensure durability and regulatory compliance.

The transfer of large modules involves logistical challenges: maximum permitted road dimensions, vibrations during transport, and anchoring techniques to the ground must be considered to ensure structural stability.

Since they are often pre-installed, it is necessary to comply with local regulations and provide access for future maintenance. Poor planning can hinder repairs or expansions.

Although insulating materials such as rock wool, expanded polyurethane, or SIP panels are used, the quality of the installation is crucial. A small mistake in joints can cause thermal bridges or acoustic leaks.

In many countries, prefabricated homes face legal loopholes or complex bureaucratic processes. Adapting to local building codes, fire resistance, and planning requirements is a constant challenge.

All of this will contribute to creating homes that are faster to build, customizable, and with a smaller environmental footprint.

Prefabricated homes are not simply a "passing trend," but a concrete response to the need for faster, more efficient, and sustainable homes. Even with the technical and regulatory challenges they face, their technological development aims to radically transform the way we think about construction.